Industry Came to Glendale

History of the Beet Sugar Factory

By Kathleen Noon, Phoenix Public Library, Historian — A paper presented at the 2000 Arizona History Convention

Enhanced (dark red font) and posted by Andrei Conovaloff, updated April 29, 2012.

History of the beet sugar factory promoted in Glendale Arizona in 1901 by W. J. Murphy. The factory was owned by 7 different sugar companies from 1901 through 1935. The plant opened August 1906 but closed in December. It was never profitable due to inadequate money, beets and water; and auctioned twice, in 1908 and 1935. The beet sugar plant operated only 4 years, from 1909 through 1913. Several companies rented space until purchased in 2011 to produce liquor, ironically in a town founded as a temperance colony.

Contents

- Introduction

- 1901 — Eastern Sugar Company, New Jersey (Murphy)

- 1903 — Eastern Sugar Company, Arizona

- 1906, July — No Water

- 1906, August — Factory Operates

- 1907 — Factory Closed and Payment Complaint

- 1908, March — Arizona Sugar Company (Davies, McKinnie)

- 1908, October — Southwestern Sugar and Land Company

- 1913 — Western Sugar & Land Company (merged with Southwestern)

- 1916 — Holly Sugar Company (bought Western)

- 1930s — Great Western Sugar Company (bought plant)

- 1935 — Philip Ringer (bought at auction, rented space)

- 2000 — Summary

- ASU Architects

- 2011 — Liquor Factory, Tasting, Sales (bought by Klemp, AZ Wine Co.)

- References

1. Introduction

In 1900, the Salt River Valley was a growing agricultural area consisting of a number of small communities connected to a modern canal and irrigation system, rail service to most parts of the valley, and fertile land compatible to crops from grain to citrus. One of these farming communities was Glendale. Located nine miles northwest of Phoenix, Glendale grew through the promotional efforts of W. J. Murphy, a successful Phoenix businessman and a founder of the Arizona Improvement Company for water and land development. Murphy held large land holdings around and in Glendale and went about the work of developing water, rail service, roads and agriculture with the hope of luring major enterprises to the community. One crop which was gaining Murphy's interest, due to the large profits it was showing in other states, was sugar beets.Sugar beets was a growing industry in the United States since the early 1880's with a number of states having factories for the purpose of turning sugar beets into granulated sugar. In the 1890's, Alfred J. McGlatchie and Robert H. Forbes, from the University of Arizona, were conducting experiments on the possibility of growing sugar beets in the Salt River Valley and Stafford areas. They released their findings in 1899 with the statement: "Sugar beets of good quality and in paying quantities can be produced in the Salt River Valley."(1) After the release of this study, W. J. Murphy became the Arizona sugar beet industries major promoter.

Murphy's planned to promote more than just sugar beet growing, he hoped to build a large factory in Glendale for the purpose of producing sugar from sugar beets. An enterprise the size Murphy intended required more capital than was available in the valley, so investors from other parts of the country were located.

2. 1901 — Eastern Sugar Company, New Jersey

In 1901 Murphy secured investors from New Jersey and Michigan and formed the Eastern Sugar Company. The company incorporated in the state of New Jersey in August, 1901 with purpose being to:

acquire by purchase or to construct, equip and maintain factories for the manufacture of sugar from sugar beets upon the lands of the company or upon any other lands, and to equip, maintain and operate the same.(2)Headquarters were listed as Jersey City, New Jersey, though most officers and most business was conducted out of Detroit, Michigan.(3)3. 1903 — Eastern Sugar Company, Arizona

In March 1903, the Eastern Sugar Company filed with the Arizona Corporation Commission and on April 8, 1903, William H. Robinson, a Phoenix attorney, was appointed to act as lawyer agent for the company in Arizona.4 The Eastern Sugar Company also filed a trust mortgage with the County Recorder in the amount of $800,000 to back up the sale of stocks and bonds. All of this activity was viewed by Phoenix newspapers as encouraging signs that the company was sincere about construction of a sugar beet factory.

Construction on a beet sugar factory, located about one mile east of Glendale's business district, began during the summer of 1903. By December, due to financial problems, construction was halted, with only a steel skeleton standing. The Eastern Sugar Company was unable to sell a sufficient number of bonds to insure further construction and went into receivership the end of 1903.5 The company remained in receivership until 1905 when W. J. Murphy was able to secure new investors from New Jersey and Michigan. These investors hired Mr. Teodor Hapke, a partner in American Construction and Supply located in Chicago, as General Contractor and agriculturist. Mr. Hapke was considered an experienced sugar man, who had instructed farmers in the Midwest in the growing of sugar beets and had written articles on the subject.6

Mr. Hapke arrived in the valley an November 5, 1905 and immediately began negotiations with the Santa Fe and Southern Pacific Railroad to add spur lines past the factory and to secure reduced shipping rates for material and equipment needed at the factory.7

When soil around the factory was found to be suited to the production of brick, Mr. Hapke, decided to produce all bricks needed in the factory's construction at the site. By December 5, 1905, the equipment, two large kilns which produced 25,000 bricks per day, were in operation.8

Mr. Hapke began securing contracts with farmers on November 14, 1905, with hope of having 4,000 acres planted in beets the first year and double the amount the next year. To help encourage beet planting he raised the price to be paid at harvest time from $4.00/ton for beets with 12-14 percent sugar content to $4.50/ton. He planned to import experienced field workers at pre-set wages, to insure quality work and to help farmers gauge costs before planting.9 By December 3, half the required contracts had been signed and the coming season looked promising.

Phoenix newspapers, to induce ranchers to grow sugar beets, wrote of the large crops and high prices paid to Michigan and Wisconsin farmers. The Arizona Republican wrote on December 3, 1905:

There's no danger of getting in too large an acreage and the more the merrier for unless all indications are at fault, the man who raises sugar beets will stand a better chance to make money than he would on any other crop.10Articles of this type were written during the entire duration of the factory's operation. It seemed the newspapers of the day could find nothing but good things to say about the venture right up to the end.The Arizona Republican, on January 5, 1906, wrote an extensive article on all phases of construction and the description given of the buildings sizes shows what an extensive undertaking the factory was:

The steel structure of the main building is now fully completed. It is five stories high in one part and three stories in another. Built on solid concrete foundations it gives every appearance of standing for ages. This building is 293 by 67 feet and is the largest of the group. The foundations for the other buildings are well under way. There is a boiler house 160 by 52 feet; a lime kiln house 80 by 52 feet; a repair shop 60 by 52 feet, and a smoke stack with a base measuring 30 by 30 feet. When complete this stack will be 165 feet in height and the material a patent brick.These buildings were seen by most people as the building of Glendale and to be architecturally an attraction for the town.11 By the end of July 1906, construction was finished, processing machinery was in place, beets had been shipped from all parts of the valley and stored in storage sheds; operations were ready to begin. The factory was ready, but the water needed was not available.In addition to these buildings named there will be a sugar warehouse of the dimensions 120 by 67 feet and the immense beet sheds 400 by 100. The office building built apart from the other structures will be of modern construction, and although small will be a handsome structure.

Water for the factory was to come from the Arizona canal, wells dug at the site and a 13,000 gallon storage tank, to be filled from the Arizona canal. But the wells were not dug in 1906 and canal water was not of the quality needed for proper operation. Water was necessary in almost every phase of production from the washing of the beets, to floating them onto great wheels carrying them to the top of the building and back down where they were sliced and made into pulp. Enormous quantities of water were needed to run the 250 horsepower steam engines of the factory's eight boilers.12 Water was to prove a major problem for the Eastern Sugar Company during the 1906 season.

Flooding had occurred in the valley during the summer of 1906 causing severe damage to the Arizona canal. Repairs took longer than expected and the factory's opening had to be postponed. The delay caused financial losses, the largest being the loss of 1,000 tons of beets in storage and an unknown amount lost in the fields.13

5. 1906, August — Factory Operates

On August 11, 1906 the Glendale Beet Sugar Factory began operations at 1:30 P.M. when General Manager Layafette Meyers threw the switch, starting the machinery. A large number of valley residents were on hand for the start-up, for the factory was seen as a major industry for the entire valley and one which was expected to bring immeasurable wealth. There was even talk of a second factory on the valley's south side if all went well with the Glendale plant.14

The first bags of sugar came off the line six days after operations started and were reported to be rich in color and as high a grade as expected. General Manager Meyers was quoted in The Phoenix Enterprise: "I can say that for a new factory, I have never seen one get into working shape in such short time as has the Glendale factory." The Paper went on to quote Meyers "that the sugar turned out today is as high in grade as any he has ever handled in any part of the country,..."15

Mr. Meyers may have been enthusiastic after one week of operations, but that enthusiasm was not to last long. One month after the factory opened, it closed for the season, on September 11, 1906. Reasons given were heavy expenses and poor quality water from the Arizona canal. Canal water was very muddy and the factory's machinery was unable to extract the mud; causing the sugar to be darker and of a poorer quality than sugar produced in California or Colorado. The company stated wells were not dug for the 1906 season, but would be by the next year, eliminating the water problem.16

At the time of start-up the beet factory was reported to have cost $750,000 with more construction needed; windows and floors were lacking in the main building. The final cost has been put at $1,000,000 though no exact figures were ever released. This amount was for the factory only, it was estimated that another $200,000 was paid to farmers the first year.17

Another problem was inexperienced labor. When operations began the factory employed 200 workers, working two 12-hour shifts at wages reported good when compared to other labor occupations. But none of these men had any prior experience in sugar beet production, most were hired only the day before or the morning of the plants opening, and this inexperience caused delays at all phases of operation.18

The factory's short run did nothing to discourage either the Eastern Sugar Company or the Phoenix newspapers in their praise of the high quality of sugar beets grown in the valley. Everyone was taking an optimistic view of the season and believed that the next season would be a complete success

6. 1907 — Plant Closed and Payment Complaint

In December 1906, the Eastern Sugar company, through W. J. Murphy, announced that the Glendale sugar factory would not operate in 1907. The reason given being a shortage of water from the Arizona canal to irrigate crops in the spring of 1907. While water was a problem, newspapers were pointing to financial troubles of the company. The Eastern Sugar Company was said to have put out an estimated $1,000,000 to build the Glendale factory, but many creditors still had large outstanding debts at the end of 1906. But Mr. Murphy was still optimistic and in December the Phoenix Enterprise quoted him:

Though the factory will not operate in 1907 preparations will be made for sugar making in 1908. {sic} during which season I expect to see the factory the big success that we all have reason to believe it will be under favorable conditions.19On January 31, 1907, a local lumber company, DeMund Lumber, filed a complaint against the Eastern Sugar Company in the amount of $8,507.89. Mr. DeMund claimed he contracted with Mr. Hapke to supply lumber and labor in the amount of $14,576.52, of which he was paid $6,068.93. To collect the balance Mr. DeMund was asking the courts for the sale of the factory and that his complaint be settled before any others. Mr. DeMund alleged that the Detroit Trust Company, Murphy Iron Works, and Quincy Engine Works all held mortgages on the factory which had not been paid The courts did not act on Mr. DeMund's complaint and the Eastern Sugar Company was given time to settle it's financial obligations.207. 1908, March — Arizona Sugar Company

The Eastern Sugar Company was unable to solve its financial problems and on March 25, 1908, the factory and land holdings of the company were sold at Sheriff's auction. The factory was purchased by the Detroit Trust Company representing the bondholders of the factory. The amount paid was $955,542.29, this figure was the amount of outstanding debts against the factory and landholdings.21

The new owners incorporated as the Arizona Sugar Company on March 26, 1908 but were not in the sugar business for long. On July 27, 1908, W. J. Murphy signed a contract with R.P. Davies and J.R. McKinnie of Colorado Springs, Colorado to take charge of the Glendale factory.22

Mr. Davies and Mr. McKinnie were both experienced sugar men who had been in the business for years in other parts of the country. Both men, along with Mr. Alfred Hand, had formed the Western Sugar and Land Company of Colorado and Mr. McKinnie was president of the Everglades Sugar and Land Company of Florida. Mr. Davies had previously turned a number of failing factories around into money making operations and he intended to do the same for the Glendale factory. The Call of the Desert magazine quoted Mr. Davies:

It may sound egotistical but we know we can make that factory a success. We haven't a doubt about it. We have had enough experience to be sure of ourselves when we take up a proposition. Why, the Grand Junction factory was a ten times worse failure than this one at Glendale.23Davies and McKinnie immediately brought in their own men to fill management positions, they were said never to trust green hands in responsible positions. Two-hundred and twenty local laborers were hired and improvements were to be made on the plant to make it an "up-to-date mill of 800 tons daily capacity."248. 1908, October — Southwestern Sugar and Land Company

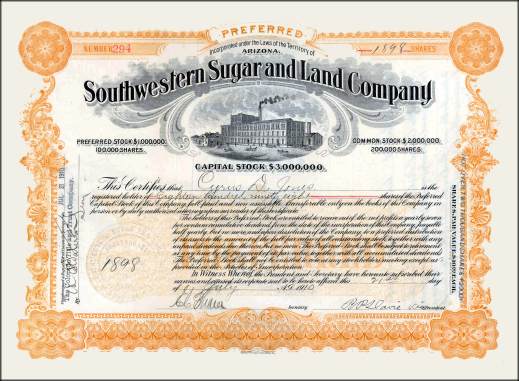

On October 20, 1908 Mr. Davies and Mr. McKinnie filed with the Arizona Corporation Commission to form the Southwestern Sugar and Land Company. The Company incorporated in what was considered a very secure financial position with $200,000 in its treasury and no bonds or debts.25

Click on picture to enlarge.

See antique stock for sale at $100With the factory in the hands of new owners, Phoenix newspapers were again reporting encouragingly of the high sugar content and longer growing season of valley beets. They were promoting the idea of two crops per year, allowing the factory to operate the year round and they were always reflecting on the financial stability of the company. But all of this enthusiasm did not encourage farmers to plant the first season. Only 67 farmers planted 4,443 acres [about 7 sq. mi.] while 7,000 acres [11 sq. mi.] were required for the factory to operate a full season of five months.26 [4443/7000 = 63% capacity]

The first bag of sugar for the 1909 season came from the factory on June 15, and was given to W. J. Murphy, who worked long and persistently to bring about the success of this venture and had to interest the right men in the industry."27

The water problems of previous years had been solved with the drilling of wells on factory property. It was discovered that just one well was able to supply the three-million gallons a day required for proper operations.28 But even with ample water the factory was only in operations for two months, closing on August 5, 1909. The sugar output for the year was 5,000,000 pounds, coming from 49,630 tons of beets at a value of $4.78/ton29 allowing the company to call the season a success, even though they made no money. Profit and loss statements were never reported, not even to the Corporation Commission which is required by law.

In February 1910, an estimated 7,500 acres [11.7 sq. mi.] were planted in beets and expectations for the coming season were high. That same month the magazine Arizona ran an article on sugar beets which began: "The cultivation of sugar beets in the Salt River Valley promises to be in the very near future one of our greatest industries."The article mentioned the high sugar content of valley beets, the high prices paid per ton, the excellent growing season, and the easy access to a market.30 But even with these encouraging factors the sugar beet industry did not prove the success everyone anticipated.

The 1910 season began on June 16, with only a small write-up in the Mesa section of the Arizona Republican, stating two carloads of beets had been shipped. In July it was reported that most of the fields had been frost bitten in November and then suffered from an extra hot spell in May.31 These weather conditions caused a sever decline in the amount of beets per acre; production fell from 25 tons per acre in 1909 to 8 tons per acre in 1910. Even with the low tonnage the Arizona Gazette was writing encouragingly of the high sugar content of the beets. They wrote: "The beets that have been shipped so far have run from 16 per cent to 20 per cent sugar. In Kansas and Colorado 14 per cent is considered very good."32 But no report of the factories closing or the final output for the year was ever given.

The 1911 season began on June 12, the earliest the factory ever begun operations, with very high expectations, the earliest the factory had ever begun operation. But only 3,200 acres [5 sq. mi.] were planted, about one-fourth less than in 1910, though the yield per acre was expected to be greater. The company was expected to pay out $200,000 for beets and $100,000 for factory labor, and aid in the prosperity of the whole valley.33 Whether these amounts were ever paid was never stated and no report was made of the factory's closing.

In the hope of increasing crop production in coming seasons, Southwestern Sugar & Land Company imported Russian families, from Southern California, to farm sugar beets in the Glendale area. The land development company of Greene and Griffin, a subsidiary of Southwestern Sugar & Land, brought 175 adults and their families to the valley on August 31, 1911. The Russians were Spiritual Christians of the Molokan religion, a group looked down upon by the Russian Orthodox Church, who had left the war-torn Russian Caucasus looking for economic and religious freedom.35 Greene & Griffin encouraged them to come to Glendale with a promise of land and a community of their own where they could worship as they pleased. Each family They bought between five and forty acres for $100 to $125 per acre at sections two miles west and one mile south of Glendale, along 75th Ave, between Glendale Ave. and Bethany Home Road. Soon more came from California, until by 1920 there were 4 separate Russian villages, each a congregation of varying Spiritual Christian faiths, with their own presbyters (lay ministers), occupying more than 8 square miles along 75th and 83rd avenues, to McDowell road near Tolleson. These families grew sugar beets and when not farming their lands, they worked on company farms or at the factory. With this added labor the sugar beet industry in the valley looked promising.34

The 1912 season opened on June 20, without much fan fair, and closed on August 12, after only a forty-day run. Tempe farmers called harvesting to a halt before all beets were harvested because they could not get them to the factory before it closed. The factory produced 3,600,000 pounds of sugar from 2,500 acres of beets and it was estimated that farmers and merchants made between $150,000 and $200,000 during the season. Mr. C. M. Culver, a director and secretary of Southwestern Sugar & Land Company, said:

We have had a very successful run, all things being considered, but it is essential that we get twice as much acreage next year as we had this. This will not only assure twice as much return to the whole body of the farmers, but will give us a longer run to complete the manufacture of the sugar.36Most current writings on the sugar beet factory put final year of operations as 1912, but in actuality the factory operated in 1913. The 1913 season began on June 25, with harvesting having begun a week earlier. The Tempe area reported 1,000 acres ready to harvest on June 23. The Arizona Republican wrote: "The beets are by far the best that the valley had produced which goes to show that farmers are becoming experienced in the art of growing beets."37 Newspapers continued to write of a successful harvest and the lack of problems in getting beets to the factory during the 1913 season. But again, the season ended after only eight weeks, the factory closing on August 16, 1913.389. 1913 — Western Sugar & Land Company

1913 was the last season the Glendale plant was in operation, on October 2, 1913, Southwestern Sugar & Land Company merged with Western Sugar & Land Company of Colorado. The intentions of the new company were to grow and process both sugar beets and sugar cane in the valley. Western Sugar & Land believed the Glendale factory could be converted to process both cane and beet; and being each was harvested at different times of the year the factory would operate most of the year.39 But neither beets or cane were harvested in Arizona after 1913 and on July 30, 1916, the Tombstone Prospector reported that the sale of the Glendale factory was postponed to allow Western Sugar & Land time to settle its debts by possible sacrifice of lands to creditors. In September 1916, R. P. Davie, president of Western Sugar & Land, was in Phoenix reporting the companies intentions to open the Glendale factory in the near future. But in October 1916, Western Sugar & Land was sold to Holly Sugar Company, who never operated the factory.40

10. 1916 — Holly Sugar Company

11. 1930s — Great Western Sugar Company

12. 1935 — Philip RingerThe Glendale beet sugar factory stood empty for twenty-two years. In the early 1930's, Great Western Sugar Company bought and removed the equipment, with extensive damage caused to floors and walls in the process. In 1935, Mr. Philip Ringer bought the factory at Sheriff's auction for $25,000 plus all outstanding debts.41

A number of companies have leased space in the factory's buildings since 1937, the first and longest being the Squirt Bottling Company. Squirt leased part of the ground floor for grapefruit concentrate production from 1937 to 1980.42

During the 1940's and 50's the Marusho Soy Sauce Company leased the boiler house to process soy sauce. The company did quite well during World War II, when no soy sauce was imported from Japan, but business fell off after the war and the company finally went out of business.43

Five different companies have leased space on the main building's ground floor since 1977. The largest was Tree-sweet Products, which leased 15,000 feet of cold storage to keep citrus fresh until shipment to grocery stores. Tree-sweet canceled their lease on October 31, 1985 due to the stopage of rail service to the factory.44

A number of newspaper articles in the 1980's reported a brewery was located at the factory during the 1930's. Mr. Jonas Ringer, current owner and son of Philip Ringer, stated in a telephone interview that a brewery at the factory was impossible due to a deed restriction on the property. The restriction states that no alcoholic beverages can be manufactured, sold or consumed on the property. This restriction may have hindered current sales of the property but to date Mr. Ringer has not had it removed.45 In August of 1951 the 184 foot chimney was struck by lighting causing a 40 foot split in the cylinder. The chimney was demolished in December 1951, because it caused a safety hazard.46

In 1979, the Beet Sugar Factory was placed on the National Register of Historic Places. This placement will allow developers tax breaks, but it also means the building cannot be torn down, and at this time it will cost more to refurbish it than to build new.47

The factory has been for sale for eight years with a number of developers and architects looking, but no offers. The City of Glendale has been interested in acquiring the property and refurbishing it as part of its downtown development; but to date, according to Mr. Ringer, the City has been unable to acquire the necessary financing.48

In 2000, almost 100 years after it's creation, the Glendale Beet Sugar Factory stands empty except for a camper repair shop in the boiler house. When the factory built it was viewed as a major industry that would bring wealth and prosperity to Glendale and the Salt River Valley. Why the sugar beet industry failed in the valley has never really been explained. Newspapers of the period wrote only encouragingly of the industry, and nothing of its failures.

A 1963 article in the Arizona Republic, reported failure was due to curly top, a disease transmitted by insects, and because of low sugar content in the beets.49 I found no evidence of either problem, sugar content in the beets was always reported to be high. I believe, failure was due to harvesting occurring at the wrong time of year and not enough acreage planted during any one season. Beets became ripe and ready for harvesting in June, July, and August the hottest months of the year in Arizona. Half of the beets were grown in Tempe and Mesa and had to be shipped by rail or horse drawn wagon. Railroad cars, but especially wagons, were not refrigerated which caused spoilage and rotting of many beets before they reached the factory. Compounding the problem was the fact that not enough acreage was ever planted in sugar beets during any one season. The factory required at least 8,000 acres [12.5 sq. mi.] of beets to run at full production, 800 tons per day, for a normal five-month season. The largest amount of acreage, 7,500 acres [11.7 sq. mi.], was planted in 1910, but still, the factory only operated two months. The average number of acres planted was 4,000 [6.3 sq. mi.], half the required amount, and if spoilage caused the loss of more beets, it only seems logical to assume that not enough beets were planted during any one season. A million dollar factory, with high expenses, must operate longer than two months a year if it is to turn a profit.

Even though the beet sugar factory was a failure, the boost it gave to the small community of Glendale was significant. The impact of the factory was felt immediately in the form of expanded building and a population increase from 300 in 1895 to 1,000 in 1910. The factory required a large labor force, which needed adequate and reasonable housing, mercantile establishments, and educational and political systems. These enterprises grew, from within and from without the community, putting Glendale well on its way to becoming the prosperous valley community of population 145,000 it is today.

(End of research by Kathleen Noon)

In September 2001, the Glendale City Council voted to appropriate $xxx for ....

ASU architectural students under the direction of Dr. ___

On July 31, 2011, The Arizona Republic announced:

Ray Klemp, owner of AZ Wine Co., and his two daughters plan to turn the site into a specialty liquor manufacturer, distributor and tasting room. Visitors will be able to sip on varieties of premium vodka, rum, tequila, gin and apple-pie-flavored liqueur and, once construction is done, tour the factory to watch production of the spirits. A

Al-Jaff, Mohamed Amin. "The Economic Feasibility of Sugar Beet Production for Sugar in the Salt River Valley of Arizona," MS thesis, Department of Agricultural Economics, University of Arizona, Tucson, 1957, 89 pages.

A. Rebekah L. Sanders, "Beet Sugar Factory in Glendale getting a new life," The Arizona Republic, July 31, 2011.

Sugar beets... U. of A. Agri. Experiment Station, Bulletin No. 23, January, 1897.

Sugar beet experiments. . .U. of A. Agri. Experiment Station, Bulletin No. 26, December, 1897.

Sugar beet experiments during 1899... U. of A. Agri. Experiment Station, Bulletin No. 31, December, 1899.

Sugar beet experiments during 1899... U. of A, Agricultural Experimental Station, Tucson, December, 1899, Bulletin No. 31.

Experimental work with sugar-beets during 1900... U. of A. Agri. Experiment Station, Bulletin No. 36, March 30, 1901.

MURPHY, W. J. Sugar-beets in the Salt River Valley . . . The Earth, August, 1908, p. 6.

DAVIE, R. P. Beet-sugar industry in the Salt River Valley . . . The Earth, August, 1909, p. 12.

GOULD, J. J. Beet-sugar industry ... The Earth, August, 1909, p. 13.

MYERS, L. The sugar beet in the Salt River Valley... The Border, October, 1909, p. 14.

MOORE, John Allen. Glendale, Arizona ... Arizona Magazine, April, 1912, p. 3.

Spiritual Christians in Arizona